Blog

It’s no secret that there a lot (and we mean a lot) of pumps out there for agricultural applications. Add up all the different brands of pumps and their categories, such as high pressure, low pressure, differing materials, sizes, etc…and it’s guaranteed to get a little confusing at times. The right diaphragm pump makes all the difference in your agricultural application, so it’s important that you choose the right one.

Today we will walk you through the factors to consider when choosing a diaphragm pump for your specific agricultural spraying application so that you have the confidence and knowledge necessary to choose the pump that will get your job done right.

FACTORS TO CONSIDER

If you are in need of a pump that moves high volumes at low pressure and is capable of running dry, then a diaphragm pump is the kind of pump that you need. Okay, so now what? There are still factors that need to be taken into account when figuring out which diaphragm pump is right for your operation.

1. Flow Rate

Flow rate is the volume of fluid flowing through the pump per unit of time. Two main factors must be considered when determining the total flow rate required by a diaphragm pump:

- Application Requirement

- Agitation Requirement

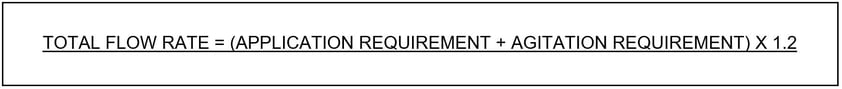

The flow rate is the sum of these two values: application requirement and agitation requirement multiplied by 1.2 (safety margin)

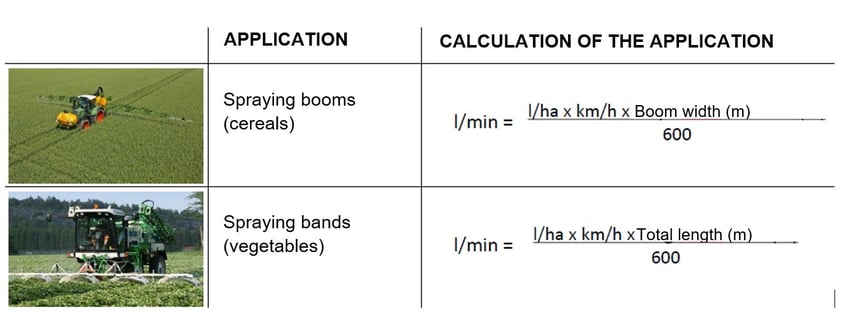

The application requirement can be found thanks to a simple formula that varies depending on the type of treatment. The figure shows the formula relating to crops protection. 20-25% of additional margin of tolerance has always to be added to the result obtained, in order to compensate for the drop-in flow rate generated by any hydraulic circuit.

The tank agitation requirements is calculated using two other formulas:

- Liquid chemicals: Tank volume in liters x 0.005 = agitation requirement (l/min)

- Soluble powders: Deposit volume in liters . 0125 = agitation requirement (l/min)

2. Pressure

Pressure is critical for nozzle operation. Lower pressures reduce speed by increasing the average droplet size and spray pattern angle. Higher pressures reduce the average droplet size and spray pattern angle.

When it comes to weed control or crop protection, low pressure setups (290 PSI) is generally used.

3. Power

Power is the amount of energy consumed per unit of time to drive the pump. The power is supplied to the pump by the means of a motor (or actuator).

Types of pump actuators:

- PTO (power take-off)

- Hydraulic motors

- Gas or electric motors

The power requirements of an agricultural diaphragm pumps depends on two factors:

- Power required for spraying application

- Power required by additional implements that can be connected through shaft at pump output

4. Liquid Properties

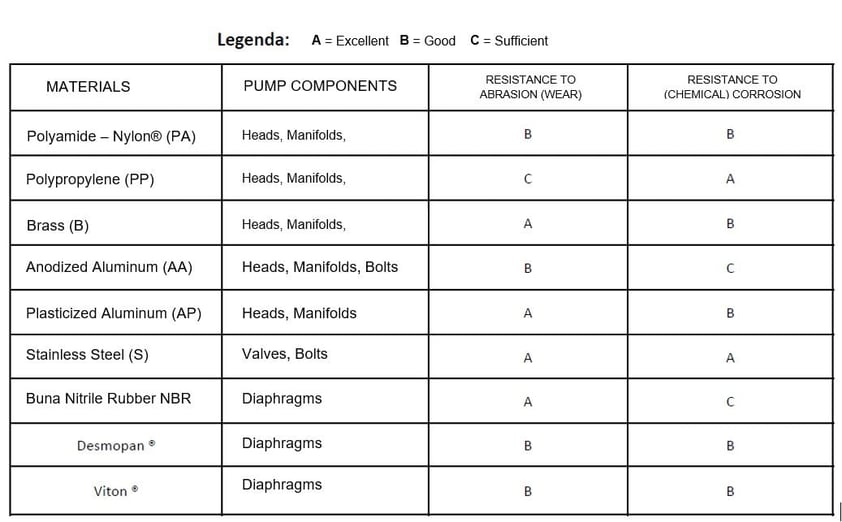

diaphragm pumps can handle very aggressive liquids and reach high pressures, but the fluid characteristics must be carefully considered when selecting pump materials. Here are the characteristics to consider:

- Viscosity: the resistance of flow. Diaphragm pumps are more suitable for water-like fluids with a viscosity at 0.001002 Pa-s (Pascal-second) at 20 degrees.

- Abrasiveness: The abrasiveness’ of a fluid is due to the presence of non-dissolved solid particles. Solid particles, especially mineral or metal-based ones (ex. copper sulphate) have a high-degree of mechanical abrasiveness and can deteriorate pump components in a very short time if not filter thoroughly.

- Corrosion: The gradual destruction of materials (normally metals) due to the chemical reaction with the environment. For this reason, corrosive fluids must be handled with diaphragm pumps that is designed with material and components designed to resist corrosion.

- Temperature: Diaphragm pumps are suitable for liquids at ambient temperature, in the range of 32° to 140° F (0° to 60° Celsius).

The NExt Step

As you can see, there is lot a homework that needs to be done to choose the ideal diaphragm pump. Once you establish all of these variables, reach out to our team and can find the solution that best meets your design, application and costing requirements.